General Description:

Application:

Applicable to waterproofing to the basements and concrete or wooden roof decks of industrial and residential buildings, also suited for waterproofing and damproofing to other architectural parts that entail materials high tensile or tearing strength and elongation.

Available Size:

Advantages:

1. Superior physical properties: high tensile strength, flexible seal around nails and cracks,compatible with different substrates.

2. Cold-applied: no flame hazard, self-adhered asphalt result in firm bonding and continuous overlapping

3. High performance cross laminated surface film: this ensures dimensional stability, high tear strength,puncture and shock resistance

4. Flexible and ease of use in detailed areas, together with other waterproofing

5. Convenience of repairing membranes: water will not migrate even any leakage occurs due to firm bonding to substrate, so fast detecting of damaged membrane and immediate repairing.

Installation:

Post-applied:

1. Substrate preparation

Remove all dust, contaminants or other foreign dirt. Keep the substrate to be dry.

2. Priming

Apply primer to substrate. During application, ensure the application is performed towards one direction and obtain even thickness, avoid leakage or accumulation and expose the primer until it is not sticky to fingers.

3. Details Treatment

Reinforce detailed areas such as inside or outside corners, drainages, expansion joints and penetration pipes.

4. Positioning

Align the membranes within right area where the membranes will be installed.

5. Membranes installation

Carefully peel down of the release film at the back, at the same time slowly push the membranes to move forward within reserved area. During the installation, the membranes shall move forward at proper speed.

The release film attached to side laps must be kept clean and free from contamination before overlapping to protect the adhesive side from being contaminated or damaged. Pull-off of membranes with excessive force is prohibited.

6. Trapped air excluding

In order to obtain firm bonding to substrate, immediately press or roll (back and forth) tightly over the installed membranes to exclude trapped air.

7. Cut edges and end laps overlapping

When overlapping cut edges, remove release film attached to side laps of previous and succeeding membranes, then bond the two adjacent membranes together (along the controlled liner/selvage). Immediately use roller to press tightly over the overlapping areas so that the trapped air is fully excluded. On end laps overlapping, the operation process follows cut edges.

.The recommended overlapping width is 80mm for below grade application, and 60mm for roofing projects.

Technical Data sheet

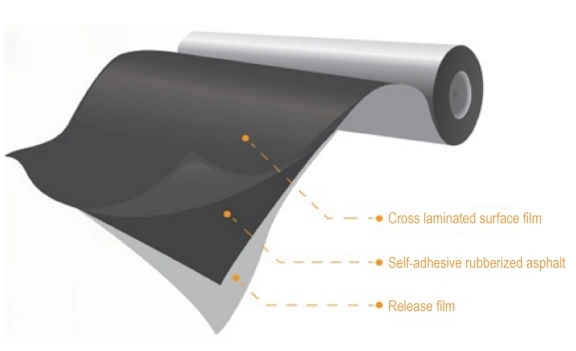

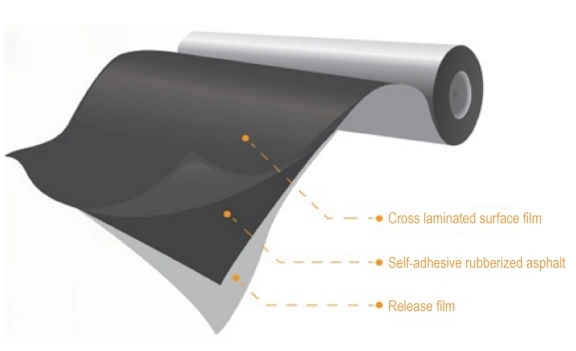

As a premier membrane designed to deliver premium in-place performance for different application environment, MBA-CL post-applied waterproofing membrane is composed of high performance cross laminated surface film, innovative special rubberized asphalt and backed release paper to maintain adhesive quality. During application, the release paper is easily removed, allowing the rubberized asphalt to bond tightly to the substrates of various materials.

Application:

Applicable to waterproofing to the basements and concrete or wooden roof decks of industrial and residential buildings, also suited for waterproofing and damproofing to other architectural parts that entail materials high tensile or tearing strength and elongation.

Available Size:

| Total thickness (mm) | Width (m) | length (m) | Remark |

| 1.5 | 1 m | 20.0 | Other specification can be offered upon requirements |

| 2.0 | 1 m | 20.0 |

Advantages:

1. Superior physical properties: high tensile strength, flexible seal around nails and cracks,compatible with different substrates.

2. Cold-applied: no flame hazard, self-adhered asphalt result in firm bonding and continuous overlapping

3. High performance cross laminated surface film: this ensures dimensional stability, high tear strength,puncture and shock resistance

4. Flexible and ease of use in detailed areas, together with other waterproofing

5. Convenience of repairing membranes: water will not migrate even any leakage occurs due to firm bonding to substrate, so fast detecting of damaged membrane and immediate repairing.

Installation:

Post-applied:

1. Substrate preparation

Remove all dust, contaminants or other foreign dirt. Keep the substrate to be dry.

2. Priming

Apply primer to substrate. During application, ensure the application is performed towards one direction and obtain even thickness, avoid leakage or accumulation and expose the primer until it is not sticky to fingers.

3. Details Treatment

Reinforce detailed areas such as inside or outside corners, drainages, expansion joints and penetration pipes.

4. Positioning

Align the membranes within right area where the membranes will be installed.

5. Membranes installation

Carefully peel down of the release film at the back, at the same time slowly push the membranes to move forward within reserved area. During the installation, the membranes shall move forward at proper speed.

The release film attached to side laps must be kept clean and free from contamination before overlapping to protect the adhesive side from being contaminated or damaged. Pull-off of membranes with excessive force is prohibited.

6. Trapped air excluding

In order to obtain firm bonding to substrate, immediately press or roll (back and forth) tightly over the installed membranes to exclude trapped air.

7. Cut edges and end laps overlapping

When overlapping cut edges, remove release film attached to side laps of previous and succeeding membranes, then bond the two adjacent membranes together (along the controlled liner/selvage). Immediately use roller to press tightly over the overlapping areas so that the trapped air is fully excluded. On end laps overlapping, the operation process follows cut edges.

.The recommended overlapping width is 80mm for below grade application, and 60mm for roofing projects.

Technical Data sheet

| NO. | Items | Value | |

| 1 | Tensile force | Tensile strength /(N/50mm) ≥ | 212 |

| Elongation at maximum tensile force/% ≥ | 320 | ||

| Elongation at bitumen break ≥ | 350 | ||

| Test phenomena | No bitumen layer sep- arated from film before the break of film | ||

| 2 | Tear Strength by nail shank/N ≥ | 100 | |

| 3 | Heat Resistance | 70°C, 2h , no displacement | |

| 4 | Low temperature flexibility/ºC | -20 | |

| No crack | |||

| 5 | Water Impermeability | 0.2MPa,120min, No Water Leakage | |

| 6 | Peel strength/ (N/mm) N ≥ | Sheet with sheet | 1.2 |

| Sheet with aluminium plate | 1.3 | ||

| 7 | Bonding retention /min ≥ | 50 | |

| 8 | Watertightness by nail shank | Pass | |

| 9 | Oil penetration test,sheets ≤ | 2 | |

| 10 | Heat Aging (70°C/168h) | Tensile retention /% N ≥ | 90 |

| Elongation at maximum tensile force/% ≥ | 380 | ||

| Low temperature flexibility /°C | -18 | ||

| No crack | |||

| 11 | Heat stability | Appearance | No blister,fold, displacement or flow |

| Dimensional variation/% W ≤ | 2.0 | ||